Heat sealer calibration is often an important element in Sterile Service Departments (SSDs). Users will want to know if their heat sealer is performing as it should be. Calibration is the easiest way to identify this.

We have already taken a look at centrifuge calibration in a previous blog back in late 2017. In this month’s blog, we will take a closer look at heat sealer calibration.

What is a heat sealer calibration?

It is important to note that there are actually three elements to calibrating your heat sealer. Think of it like baking a cake. You will probably have key ingredients such as eggs, flour and butter. Without all three of these in the right quantities, you won’t produce a very good cake.

Heat sealer calibration is similar. You need to make sure you calibrate all three parameters in order to guarantee a good seal. These parameters are speed, temperature and force. You measure speed in metres per minute and temperature in degrees Celsius (°C). Whilst you measure the force in Newtons (N). It is no good just calibrating one of these parameters and not the others. For example, if the temperature is at an optimum level, but the speed is too slow, the pouch will melt. Similarly, if both the temperature and speed is right, but the force is not enough, the pouch will not seal properly.

What steps are involved in heat sealer calibration?

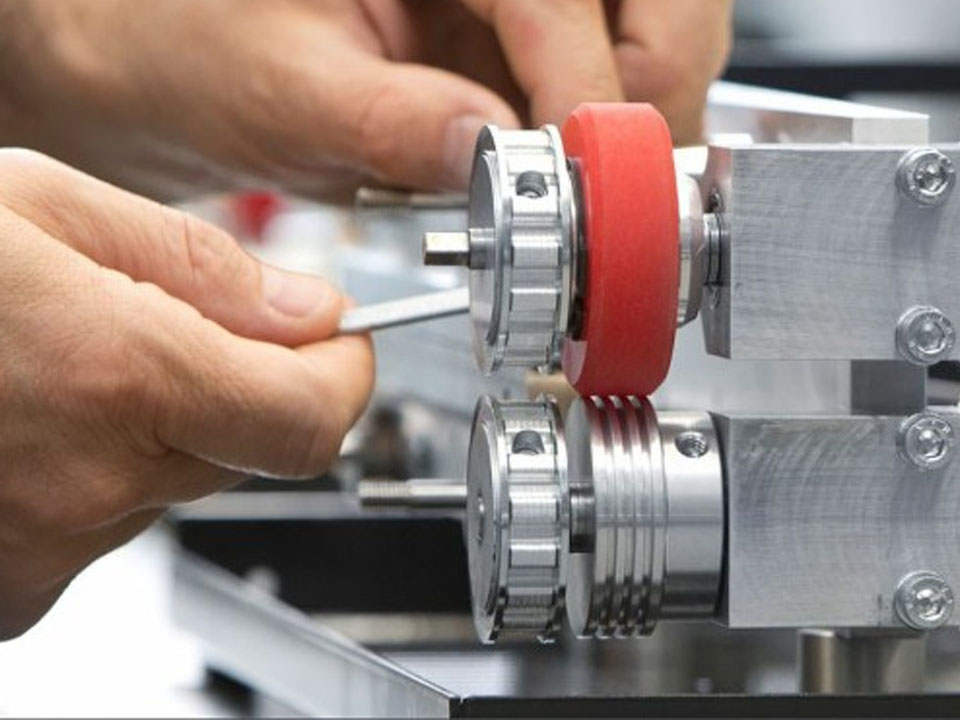

It is possible to perform a heat sealer calibration using specially calibrated equipment. For temperature, this involves placing a calibrated thermometer on the heater bars. Speed involves measuring the time is takes for a mark placed on the transport belt to perform one revolution. You measure this using a calibrated tachometer fitted with a customised wheel. Finally, force can be calibrated by taking out the part of the heat sealer which determines the force. The part is then rigged up to a customised strain gauge and the force is measured in Newtons.

Heat sealer calibration frequency. How often should I calibrate my heat sealer?

How often you calibrate your heat sealer will of course depend on how often you use it. Usually, one annual calibration is sufficient, but some very busy SSDs and manufacturing sites may want to have two calibrations a year. Furthermore, you would usually combine a calibration with a preventative maintenance service.

Calibration is actually only one element that an SSD can employ to check their heat sealer is working as intended. There are also testing methods such as Seal Check, Ink Test PRO and pouch destruction. I have covered this topic in a previous blog back in 2016. You can employ these additional testing methods at regular intervals to compliment the heat sealer calibration. For example, Seal Checks and Ink Tests can be carried out every day, before production starts. Furthermore, you can also carry out a pouch destruction test every 3 to 6 months.

How Henderson Biomedical can help

Henderson Biomedical has been calibrating heat sealers for over 20 years. This includes rotary and impulse types. We are the official UK distributor of Hawo, a leading German manufacturer of heat sealers. However, we are familiar with all types of heat sealer and we are able to calibrate other makes including Gandus, Famos and Astrapac. For more information, you can contact our friendly team by calling 020 8663 4610 or you can email us using the contact form.