Centrifuge calibration- it’s what we have been doing for over 30 years. During this time, we have frequently been asked the same question: how often should I calibrate my centrifuge in any given year? It’s a difficult question to answer as it does depend on a number of factors. In this month’s blog, we try to answer this question and give you some sound advice on calibrating your centrifuge.

What is calibration and what types are available?

Before we answer the question on how often you perform a centrifuge calibration, it is important to understand what calibration actually is and what types of calibration are available to you.

Calibration defined as ‘the means to determine or check the graduation of any instrument giving quantitative measurements’. In simple terms, you want to know that the value your device is showing is really what it is. So, if the speed of your centrifuge is showing 3,000 rpm, a calibrated digital tachometer will be used to determine whether this is the case. It could be that the tachometer is showing 3,100 rpm and in this case, remedial work would need to be undertaken to make the centrifuge show the correct speed.

There are usually three parameters that you can assess during a centrifuge calibration: speed, time and temperature. You can choose a standard calibration where an engineer will use a calibrated piece of equipment (usually traceable to NPL standards) and they will perform one check Alternatively, you can opt for a UKAS calibration. This is a higher level of which ensures compliance with ISO 17025, which may or may not be required by the user. If your laboratory needs to comply with ISO 15189, then it is likely that a UKAS calibration of your equipment will be required. When calibrating to UKAS level, the procedure involved in carrying out the calibration is much more rigorous, often with numerous checks over a period of time.

Calibrating your centrifuge

So, to the crucial question that everyone wants to know the answer to: how often should I calibrated my centrifuge? The answer to this question does really depend on the amount of use. A centrifuge which is infrequently used is not as likely to need calibrating as much as a centrifuge which is used much more frequently. If the centrifuge is being used heavily, say for 6-8 hours a day, five days a week, then the variance of change is likely to be higher as wear and tear takes their toll on key components. In this instance, we would recommend two calibrations a year, spread out over 6 month intervals.

Analysis of data

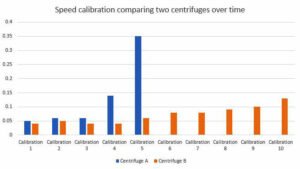

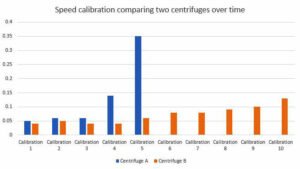

To illustrate this point, we took data from real life users from our own database. We took two centrifuges of the same make and model as an example. The first centrifuge (known as centrifuge A) has one speed calibration a year. The second centrifuge (known as centrifuge B) has two speed calibrations a year.

As with all calibrations, a value is set and that value is checked against independently calibrated equipment. We can see that the variance increases over time for both instruments over time. This is to be expected because, as a centrifuge ages, the accuracy of readings can suffer unless key components are replaced.

However, what is most interesting is that the variance never goes above 0.13% for centrifuge B (the one calibrated every six months). However, the variance for centrifuge A, which is calibrated every 12 months has a maximum variance of 0.35%.

Both are of course, still within acceptable tolerance limits (usually +/- 2%), but we can clearly demonstrate with this example that calibrating your centrifuge twice a year means the centrifuge reading is more accurate.

It is worth noting that both centrifuges were used intermittently for around 2 to 4 hours a day. One would expect these values to be much larger if the centrifuge is being used heavily.

Other factors to consider

We have seen how parameters can tend to become skewed over time. Performing a calibration will only inform the user if set values are incorrect. What is more important is that repair work is carried out to ensure that the centrifuge is rectified. Simply leaving it will only make matters worse. The centrifuge should be properly serviced and repaired when needed. This will ensure that parts of the centrifuge are in optimum condition, thus minimising any variance.

It is also important to consider what substance is being spun. If the substance is not that critical to life and the user only wants to perform basic separation, then there is an argument that no calibration is needed at all. However, if you are processing blood that could potentially be put back into a patient, then two calibrations would certainly be needed. This is because it is vital that the user knows the centrifuge parameters being used are accurate. If the speed is out, then the separation results will not be as good and this could be harmful to the health of the patient.

Conclusion

When calibrating your centrifuge, first ask the question: do I need calibration at all? If you are certain you do, then consider how much the centrifuge is going to be used. If the centrifuge is going to be used at least 6-8 hours a day, then you may want to consider 2 calibrations a year. However, do take into account what you are spinning and how crucial it is to have accurate readings.

Henderson Biomedical specialise in the calibration of laboratory centrifuges. We have been established for over 30 years and thus we are ideally placed to offer advice on centrifuge calibration. If you need any advice or help with regards to centrifuge calibration, contact our friendly team on 020 8663 4610.