Many Clinical Sterile Service Departments (CSSDs) use heat sealed pouches to protect surgical instruments such as scalpels, hemostats and forceps from contamination. These heat sealed pouches are usually clear on one side, allowing the user to see what is inside and paper on the other side to allow the steam from an autoclave to penetrate and sterilise the instrument. These pouches are then sealed by a heat sealer (usually of the rotary type) before being placed inside the autoclave.

However, there are some CSSDs which use the self-seal pouches instead of the heat sealed ones. These are similar to the heat sealed pouches except that at the opening, there is a self-adhesive flap which one sticks down, much like an postage envelope.

There are a number of problems with self-seal pouches. Firstly, it is very easy to accidentally get creases in the seal when the user sticks the flap down. This is particularly true when using larger pouches. Secondly, if the self-adhesive flap is not stuck down straight, then there will be gaps and this will completely compromise the sterility of the contents inside. These gaps might be large and easy to spot with the naked eye, or they will be so small, that it would be impossible for one to notice by visually checking by eye.

A recent collaborative study carried out by Klaus Roth, Christine Wuhrer and Jianbin Wang of SMP GmbH and Peter Heeg of the Eberhard Karls University in Tüebingen, Germany found that self- seal pouches offered less security than heat sealed pouches when tested under identical conditions.

Examinations were performed on new pouches before and after sterilisation as well as artificially aged pouches. The investigation into the two types of pouches was prompted by observations that pressure fluctuations during the sterilisation process exerts high levels of stresses on the sealing seams.

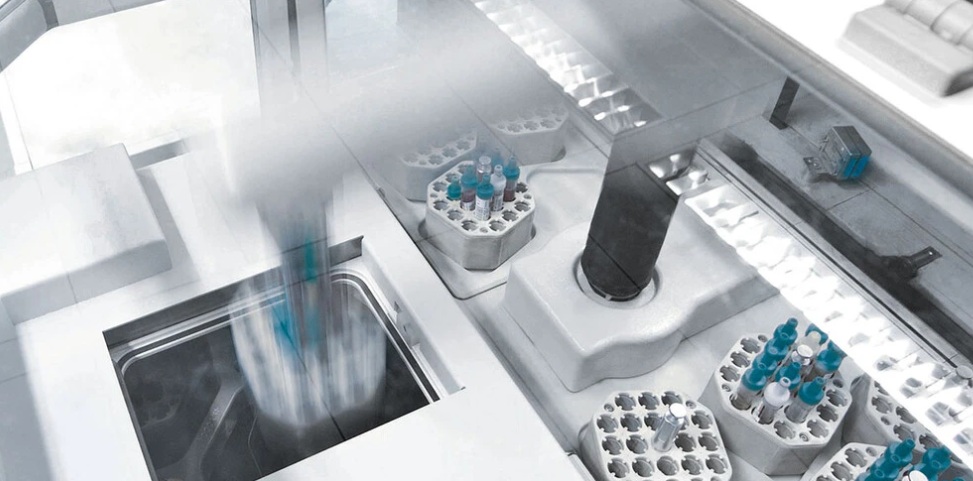

Sterilisation pouches in varying sizes from different manufacturers such as Stericlin, Westfield and Amcor were loaded with defined contents and closed by means of a heat sealer or manually by hand. Once this had been done, each pouch was cut open on the opposite sides, its contents removed and two air nozzles were inserted into the pouch. A pressure of 150 bar was then injected into the pouch via one air nozzle. A manometer was attached to the end of the second nozzle. Then the pouch was immersed in water and any air bubbles that appeared from the seam were recorded.

Of all 147 investigated self-seal pouches, 47 were found to be leaky. Leakages were particularly prevalent in larger pouches containing instruments like hose sets. In contrast, every single heat sealed pouch was found to have a tight seal which meant they conformed to ISO EN 11607-1 and BS EN 868-5.

The study carried out by the SMP GmbH and the Eberhard Karls University recommended that the use of self-seal pouches should be discontinued.

Some manufacturers such as VP Stericlin have discontinued their range of self-seal pouches as they are not confident in their levels of sterility. Other manufacturers continue to make self-seal pouches, but it does seem that the days of these sorts of pouches are numbered.