Lab automation is no longer a futuristic concept, it’s a practical necessity for laboratories across the United Kingdom. Faced with mounting workloads, skills shortages and growing expectations for precision and traceability, British laboratories are increasingly embracing automation to maintain competitiveness and reliability. The goal is straightforward: allow machines to handle repetitive, precision-dependent tasks, while human specialists focus on analysis, system optimisation and innovation.

A recent study published in Analytical & Bioanalytical Chemistry highlights how automation enhances reproducibility, improves data integrity and accelerates processing across scientific disciplines (Can I benefit from laboratory automation?, Springer, 2023). Similarly, institutions such as Imperial College London and the University of Cambridge have integrated advanced robotic systems to streamline workflows, increase experimental throughput, and reduce manual error in complex research environments. In clinical diagnostics, the NHS continues to expand automated sample handling to improve turnaround times and reduce technician strain. In short, automation has become the backbone of modern laboratory practice in the UK.

The Tangible Benefits of Laboratory Automation

From an engineering perspective, the advantages of laboratory automation can be categorised into four main domains:

- Operational efficiency: Automated systems can operate continuously, enabling laboratories to process a higher volume of samples within a shorter timeframe (MLO-Online, 2021).

- Quality and consistency: Automated instruments perform with precision and repeatability that is difficult to achieve manually. Centrifugation parameters acceleration, temperature, deceleration can be replicated accurately across runs, improving analytical reliability.

- Safety and ergonomics: Automation limits repetitive strain and reduces exposure to hazardous materials, vital in biomedical and clinical laboratories.

- Data and compliance: Integration with Laboratory Information Management Systems (LIMS) ensures every stage of the workflow is digitally recorded and auditable crucial for ISO 15189 and UKAS-accredited facilities (Astech Projects, 2024).

These advantages are not theoretical. The Medical Laboratory Observer reported that automated pre-analytical systems including robotic centrifugation improved SARS-CoV-2 testing throughput and consistency while lowering the risk of contamination (MLO, 2021). Similarly, NHS laboratories that adopted total laboratory automation observed measurable gains in sample turnaround and error reduction. The engineering evidence is clear: automation transforms laboratory reliability and productivity.

Centrifuges- The Unsung Workhorse of Automation

Among all laboratory instruments, the centrifuge remains a cornerstone of sample preparation. Yet until recently, it was one of the least automated processes. Conventional centrifugation involves manual balancing, loading and unloading — tasks that are time-consuming and susceptible to error.

Modern automated centrifuges now eliminate these bottlenecks. Integrated within robotic workflows, they can automatically receive, spin, and release samples without manual intervention. A study published in the Journal of Open Hardware describes a fully automated centrifugation system integrated with liquid-handling robots, enabling hands-free sample processing and complete digital traceability (A Smart Centrifuge for Automated Sample Processing, 2022).

In such systems, centrifuges communicate with robotic arms, conveyors, and LIMS platforms. The result: shorter processing times, improved consistency, and a safer, more streamlined workflow.

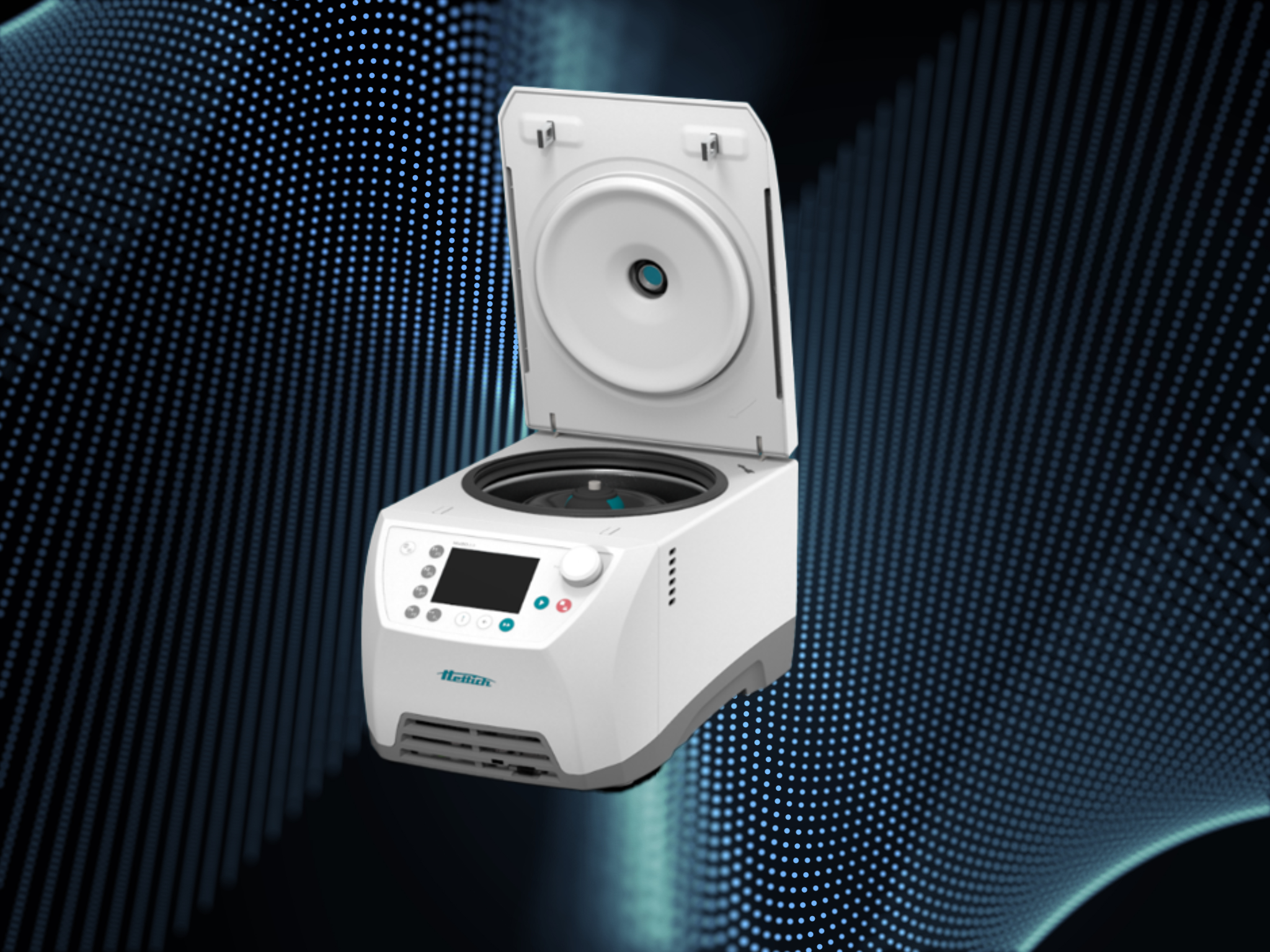

The Hettich SBS 300 Robotic Centrifuge

A prime example of lab automation is the Hettich SBS 300 Robotic Centrifuge a system purpose-built for automated, high-throughput laboratories. Unlike traditional instruments retrofitted for automation, the SBS 300 Robotic is designed from the outset for integration.

Key technical characteristics include:

- Flexible access: Available in both top- and front-loading configurations, compatible with robotic arms or SCARA systems (Hettich Lab, 2024).

- High performance: Speeds up to 6,300 rpm (4,615 × g) with a capacity for two microtitre plates, ensuring industrial-grade performance in a compact footprint.

- Continuous operation: Engineered for 24/7 reliability, with durable components suitable for high-frequency automated workflows.

- Integration-ready design: Open communication interfaces allow seamless connectivity with automation lines, simplifying commissioning and long-term maintenance.

From an engineering standpoint, this centrifuge demonstrates modularity, interoperability, and precision, the three critical parameters that determine automation success.

How Henderson Biomedical can help

Henderson Biomedical is the exclusive UK partner for the automated range of Hettich centrifuges. These centrifuges are an essential part of the lab automation setup. We are able to work with integrators to recommend the best centrifuge solution, depending on your needs.

For more information on how we can help you, please call us on 020 8663 4610, or you can use our online form.