Clinical Sterile Service Departments (CSSDs) often use a combination of pouches and wrapping depending on the type of surgical instrument they are protecting from contamination. In last month’s blog, we looked at self-seal pouches and how their sterility is questionable in comparison to heat sealed pouches. Pouches of any type are generally used for smaller surgical instruments, whilst wrapping is used for larger items such as surgical trays and pans.

However, it is not just self-seal pouches that have been put under the spotlight in recent times. Some critics have also questioned the true sterility of wrapped surgical items. This is because the number of layers and type of material one chooses to use to wrap larger items varies between CSSDs and there is no standard to define the number of wrapping layers. Therefore, CSSDs often make their own decision on what they regard as sufficient. Indeed many hospitals simply base their wrapping choices on tradition and what the hospital is used to. This can pose a serious risk since the correct packaging of surgical instrument sets before sterilisation is vital in reducing the risk of surgical site infections (SSIs).

Medical devices used in surgical procedures are classified as ‘critical’ patient care items according to the Spaulding classification system which was initially devised in 1968 and is still in use today. It is for this reason that these instruments are appropriately packaged before sterilisation, thus minimising the risk of SSIs.

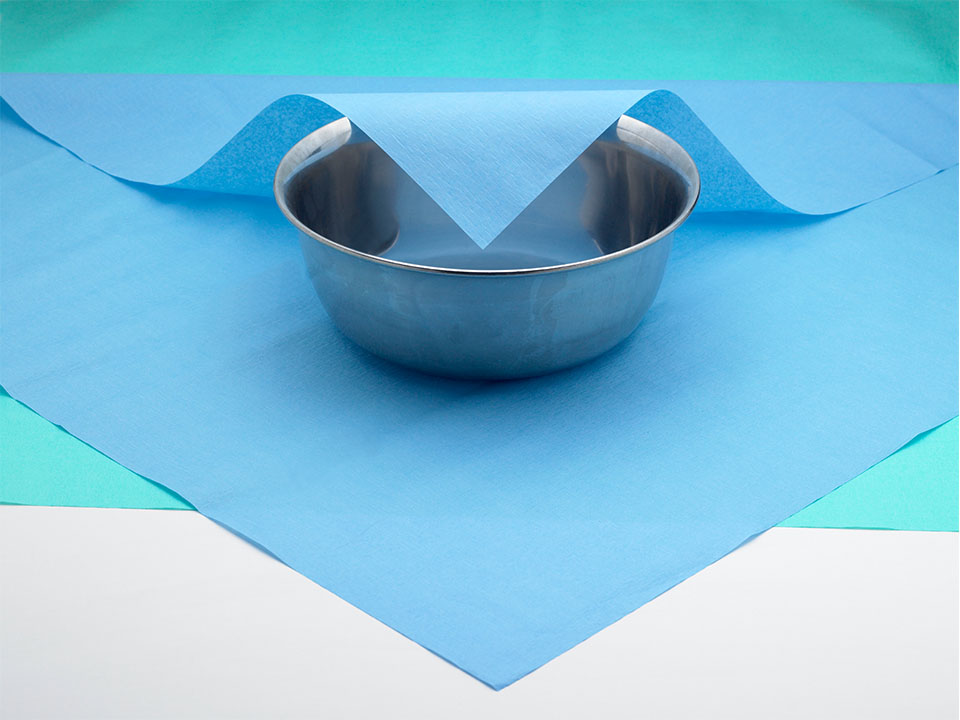

The wrapping of larger surgical instruments has come a long way over the years. Traditionally, linen was the preferred choice for the outer wrap, even though it is a poor Sterile Barrier System (SBS) and is prone to attracting and trapping dust particles. Things have moved on now with the introduction of newer technologies such as non-woven polypropylene fibres which is not only tear resistant but also offers excellent sterile barrier properties. Materials for wrapping continue to evolve, perhaps now is the time to see an evolution in wrapping procedures to further reduce the risk of potential infection?

Of course, each hospital will claim that their system of wrapping is sufficient and therefore they might be resistant to change. Indeed, the objective of any packaging system should be to enable the penetration of the sterile chemicals, whilst protecting the instruments from contact contamination during handling. The package should provide an effective SBS that protects against microbial penetration as well as maintain the sterility of contents inside. So long as this is achieved, then it really doesn’t matter what method the department has used to wrap their surgical instruments.

There is also a secondary factor to take into account when wrapping and that is cost. The single wrap method saves on time and wrapping materials, but arguably compromises the sterility of the contents inside. Interleaved wrapping offers a better SBS, but does cost more. Standard crepe paper is a lot less expensive too, but some CSSDs might prefer to use crepe sensitive paper which is softer on the fingers when wrapping.

Some might say that ISO 11607 (packaging for terminally sterilized medical devices) sets the standard and that should be followed. However, ISO 11607 does not state how many layers of wrapping should be used.

It is certainly a grey area that needs to be addressed in future. One thing is for sure and that is CSSD managers should review their practices but at the same time ensure that it corresponds with existing practices and protocols. A full risk assessment should be carried out before considering a change in procedure and packaging system. For help and advice, you can contact VP Stericlin who are will be able to recommend best practices and perhaps offer a new product which can save time and money as well as improve the SBS. Henderson Biomedical is the official UK distributor of VP Stericlin products and can also offer sound advice on which product and process is right for you.